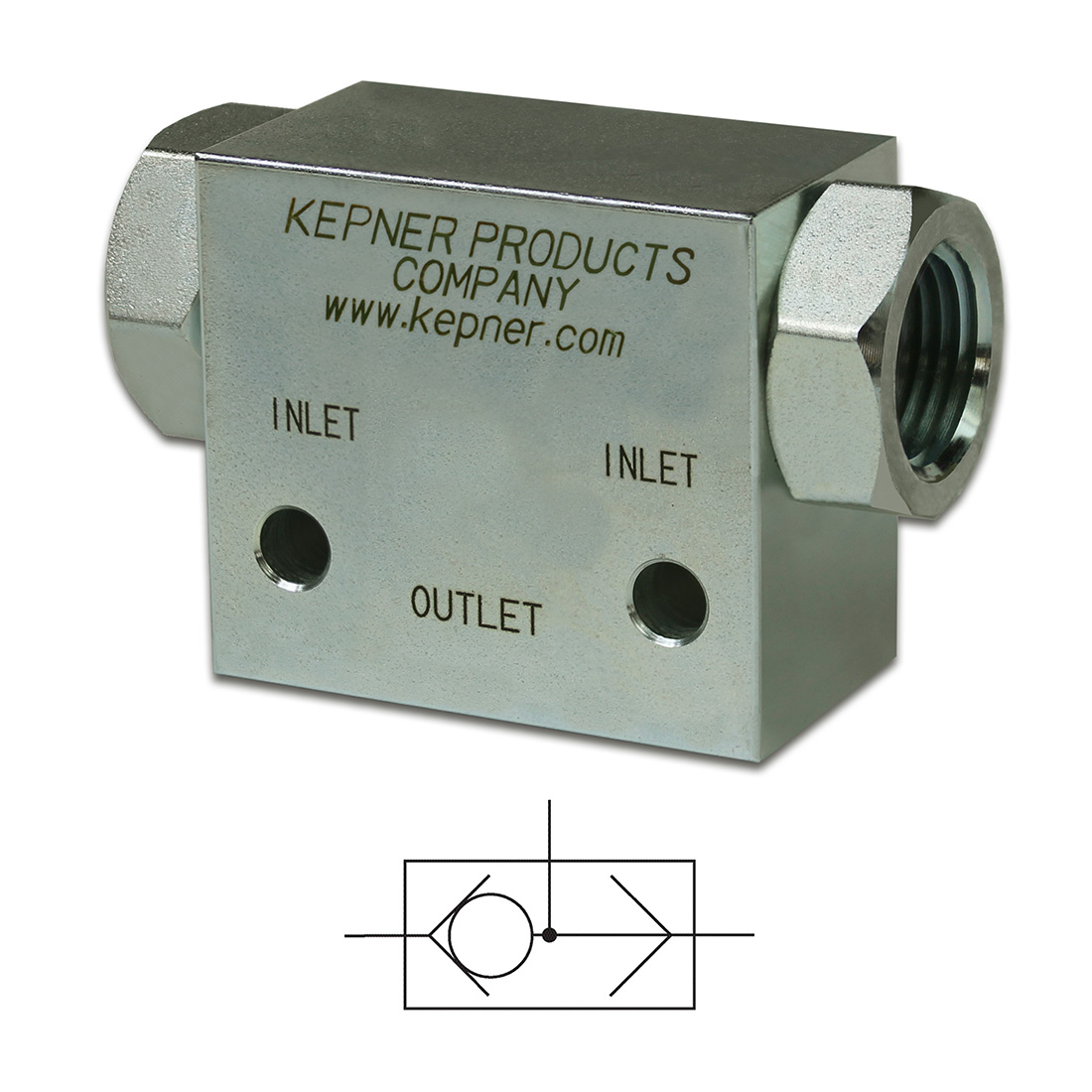

Inline Shuttle Valves

The shuttle valve permits flow from either of two inlet ports to a common outlet. A free floating metal ball shuttles according to the relative pressure at the two inlets. The higher pressure inlet flows through the valve and moves the ball to close the opposite inlet. Kepner's Flexible Seal Seat™ combines metal-to-metal contact with a resilient seal seat to ensure bubble-tight shutoff of liquid or gas, and long service life. Shuttle valves can also flow in the reverse direction, and relieve system pressure when input is removed. Standard and specialty valves handle a wide variety of control applications, including use in logic circuits, for pilot signal input and venting, dual input pilot control, and for switching to alternate or standby systems.

Features and Benefits:

- Flexible Seal Seat™ for zero leak (bubble-tight) seal at closed port

- Non-biased free floating shuttle ball with short travel path

- Minimal pressure differential shifting

- O-Ring seal positively secured

- Unobstructed flow paths allow full flow and minimal pressure drop

Standard Valve Specifications:

- See Applications for selection/ limitation notes about O-Ring and Valve materials

- End Connections/Sizes: 1/8 inch to 3/4 inch FPT

- Body Materials: Brass, Steel, 303 Stainless Steel

- O-Ring Seals: Buna-N, Teflon®, Viton®, other materials available

- Temperature: -300°F to 450°F (-184°C to 232°C), O-Ring dependent

- Operating Pressure: to 3000 PSI (207 bar)

- Flow: to 60 GPM (227 LPM)