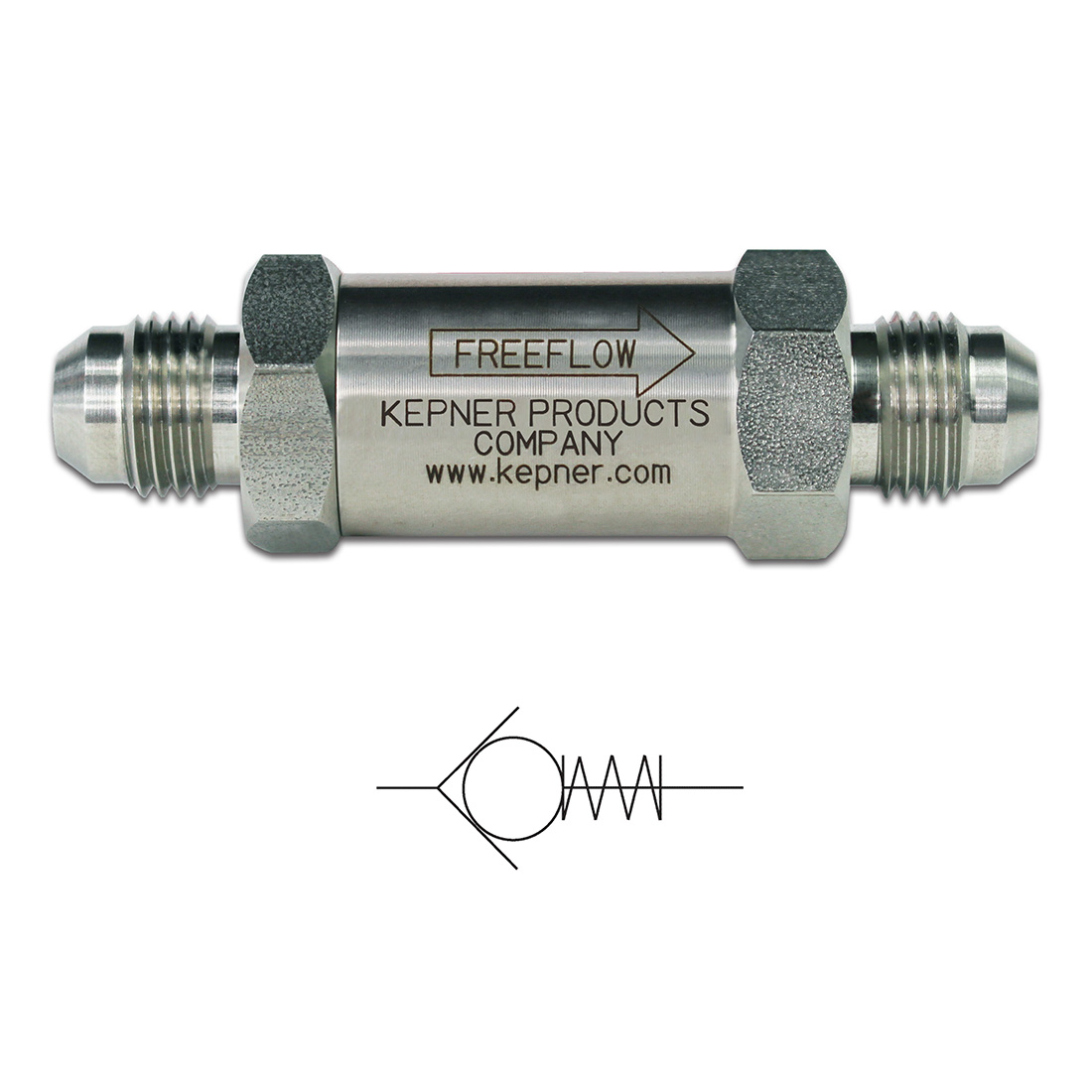

INLINE CHECK AND RELIEF VALVES

These spring-operated poppet valves, with optional relief settings, allow free flow in only one direction and prevent backflow - sometimes referred to as "backflow preventor", "flow stop", or "non-return" valve. They also are used for relief and by-pass functions; however, they should not be used as safety relief valves. Kepner's Flexible Seal Seat™ combines metal-to-metal contact with a resilient seal ensuring dependable bubble-tight shutoff liquid or gas, and long service life. Standard and specialty valve desigen handle a wide variety of applications.

Features and Benefits:

- Flexible Seal Seat™ for zero leak (bubble-tight) seal at low and high pressures

- O-Ring seal positively secured

- Generous flow passages allow full flow with minimal pressure drop

Standard Valve Specifications:

- See notes below for Applications and O-Ring / Valve materials selection and limitation notes

- End Connections: Pipe or Tube (NPT, JIC; 12 combinations)

- Port Sizes: 1/8 inch to 3 inch (3.2 mm to 76 mm)

- Body Materials: Aluminum, Brass, Steel, 303 or 316 Stainless Steel

- O-Ring Seals: Buna-N, Neoprene, Viton®, EP, others available

- Temperature: -300°F to 450°F (-184°C to 232°C), O-Ring dependent

- Check Crack Pressure: 1 to 2 PSI (.07 bar to .14 bar)

- Relief/Check Crack Pressures: 5 PSI (.35 bar), 10 PSI (0.7 bar), 25 PSI (1.7 bar), 50 PSI (3.5 bar) and 65 PSI (4.5 bar), others available

- Operating Pressure: to 6000 PSI (207 bar)

- Flow: to 500 GPM (1893 LPM)

Related Documents:

- Application and Product Suitability

- Check Valve Features FAQ

- Fixed Orifice Flow Control Restrictor Valves & Applications

- Flexible Seal Seat

- Inline Check Valve Applications

- Inline Check Valves Gas Flow

- Inline Valves Installation & Care

- Inline Valves Summary Applications

- Inline Valve Cleaning and Repair

- Measure Surge Pressure Inline Check Valve

- O-Ring Seal Selection Guide

- Relief Check Valves

- Valve Material Selection Safety Warning

Consult Factory or Distributor for more help. Customer/user is solely responsible to select products suitable for their specific application requirements and ensuring proper installation, operation and maintenance of these products. Improper selection or use of products can cause personal injury or property damage. All sales are subject to Kepner Products Company Standard Terms and Conditions of Sale.